Dave's Place

Midland Ross Booster

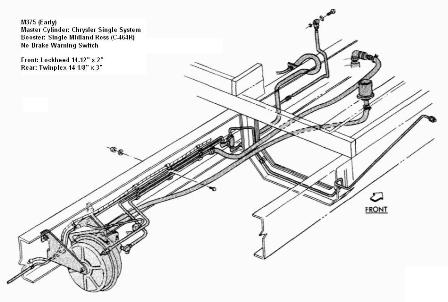

GENERAL INFORMATIONEarly built M300 and M375 Motor Home chassis are equipped with vacuum hydraulic power brakes, as follows:

The principles of operation and applicable service procedures for the power brake units used on Motor Home chassis are virtually identical except for certain minor details. Both the C-490G and C-464R booster units are single diaphragm vacuum booster units made up of three basic functional components; the power section, the hydraulic slave cylinder and the vacuum control valve. A disassembled view of a typical single diaphragm booster unit is shown in Figure 3.

|

C-490G |

||||||||||||||||||||||||||||||||||||||||||||||||

M-300C-490G Also known as Hypower Boosters Precision Rebuilders, Inc. Figure 1 |

M-375C-464R Also known as Hypower Boosters Precision Rebuilders, Inc.  Figure 2 |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Figure 1 |

|||||||||||||||||||||||||||||||||||||||||||||||||

SYSTEM TESTS FOR LEAKAGE

If in-vehicle tests and inspection show that the vacuum booster unit is the cause of brake system malfunction, the vacuum booster must be removed for service or reconditioning. |

|||||||||||||||||||||||||||||||||||||||||||||||||

SERVICE DIAGNOSIS

|

|||||||||||||||||||||||||||||||||||||||||||||||||

BENCH SERVICE PROCEDURESRemoval (Figure 4)

|

Figure 4 - Removing Booster Unit |

||||||||||||||||||||||||||||||||||||||||||||||||

(Disassembly)The following bench service procedures are applicable to both the Midland C-490G and C-464R single diaphragm brake boosters.

CLEANING AND INSPECTIONWash all metal parts in alcohol. Wipe thoroughly with clean cloth and dry all internal passages with compressed air. Inspect parts and replace all which are worn or damaged. Check front and rear chamber sections for dents. A dented chamber body can cause brakes to fail to release. Inspect the slave cylinder body. If there is any evidence of corrosion in either the slave cylinder bore or control valve bore, the slave cylinder body should be replaced. The push-rod must be perfectly smooth to prevent seal damage and leaks. Replace if rough or damaged. Never grind off push-rod end. If the control valve disc assembly is pitted or damaged, replace with new disc assembly and spring. Disassemble the slave cylinder piston assembly and clean it thoroughly to insure proper check valve operation. The slave cylinder piston assembly should not require replacement unless a definite hydraulic leak was evident before disassembly or a major overhaul is being performed. If a leak was evident, replace piston assembly rubber cup and control piston cup. Always replace the control valve diaphragm, all rubber cups, seals, and spring during reassembly. Reassembly

Bleeding The Hydraulic System (With Vacuum Hydraulic Boosters)Before bleeding hydraulic system on chassis equipped with vacuum brake boosters, the vacuum must be completely eliminated from the booster system. Disconnect manifold tube at booster side of manifold check valve (engine stopped). CAUTION: When air pressure brake bleeding equipment is used, do not apply more than 25 to 35 pounds of pressure. A piston stop is provided in the slave cylinder to prevent damage to the return spring while bleeding the brakes. This damage can occur only when the brakes are bledwith vacuum present in the booster system. WARNING: Do not lubricate diaphragm type boosters. |

|||||||||||||||||||||||||||||||||||||||||||||||||