GENERAL INFORMATION

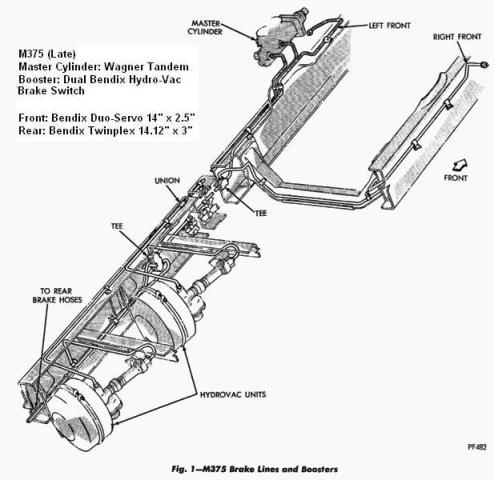

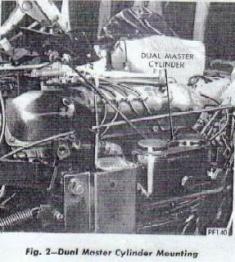

The dual master cylinder used with the split hydraulic service brake system on M-375

chassis produced after February 1971 (Fig. 2) is a split-ratio, dual reservoir device

with a 1.75 inch bore. The front piston displaces 40 percent and the rear piston

displaces 60 per cent. The rear outlet is connected to a frame mounted Bendix Hydrovc

unit which is in turn connected to the wheel cylinder on each of the front wheel brake

assemblies and to one wheel cylinder on each of the rear wheel brake assemblies. The

front outlet is connected to a second frame-mounted Bendix Hydrovac unit which is

connected to the other wheel cylinder in each of the rear wheel brake assemblies. If

these components are disconnected for any reason, be careful that the split hydraulic

brake system on the M-375 chassis is reconnected exactly as it was disconnected (Fig. 1,

also see "Brake Hose and Tubing" this Group).

|

|

Figure 1

|

Figure 2

|

SERVICE PROCEDURES

Disassembly

- Loosen shouldered master cylinder cover bolt.

- Lift off reservoir cover and cover seal. Pour out any excess brake fluid and stroke

piston to force residual fluid through outlet ports.

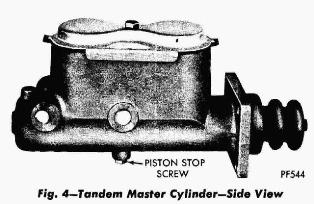

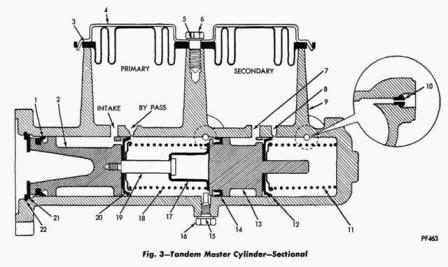

- Remove piston stop bolt and gasket from bottom of reservoir housing (Fig. 3 and 4).

- Remove retainer ring from groove in push-rod end of cylinder bore with snap ring pliers.

- Remove stop plate. All internal parts should slide out of cylinder bore easily. If they

do not, apply rompressed air carefully at front outlet port. If parts do not come out of

bore easily, examine bore carefully for damage which may eliminate the possibility of

reconditioning the master cylinder. If such damage is found, replace the master cylinder.

|

Figure 4

|

Figure 3

LEGEND FOR FIGURE 3

|

|

1. Rear Piston Seal Cup

2. Rear Piston

3. Cover Seal

4. Reservoir Cover

5. Gasket

6. Cover Bolt

7. Intake Port

8. By Pass Port

|

9. Reservoir Housing

10. Tube Seat

11. Front Piston Return Spring

12. Front Piston Pressure Cup

13. Floating Front Piston

14. Front Piston Seal Cup

15. Gasket

|

16. Stop Bolt

17. Rear Return Spring Retainer

18. Rear Return Spring

19. Rear Piston Stop Pin

20. Rear Piston Pressure Cup

21. Stop Plate

22. Retainer Ring

|

Cleaning and Inspection

Clean all parts in clean brake fluid or alcohol. If the reservoir housing is clegreased,

finish clean to remove all trace of other solvents. Inspect the cylinder bore for scratches

or corrosion. Minor blemishes can be removed with crocus cloth.

DO NOT OVERSIZE CYLINDER OVER NOMINAL INSIDE DIAMETER.

DO NOT HONE!

Check by-pass ports in both reservoirs to make sure that they are open and free of burrs.

Probe parts with soft copper wire 0.020" in diameter or smaller. Do not use steel wire to

check ports. This may scratch master cylinder or cause burrs in ports.

Remove and discard all rubber parts. All rubber parts are included in the repair kit which

is available from regular service parts sources.

|

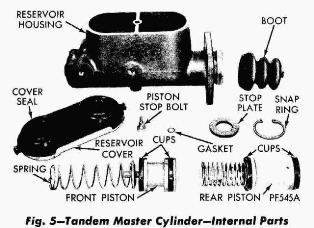

Assembly (Fig. 5)

- Coat all parts with a liberal amount of brake fluid.

- Install rubber seal cup on rear piston with cup facing rear (toward open end of cylinder).

NOTE:

All other cups face in the opposite direction (toward closed end of cylinder).

- Stack and install front piston spring, pressure cup and piston in cylinder bore.

- Install piston stop bolt and new gasket, making sure that bolt enters cylinder bore

behind rear of front piston. The new gasket is necessary to prevent leaks.

- Assemble and install rear piston parts in cylinder bore.

- Install stop plate in cylinder bore.

- Compress all parts in cylinder bore and install retainer ring in groove.

- Install reservoir cover and seal. Install push rod boot.

|

Figure 5

|